Production

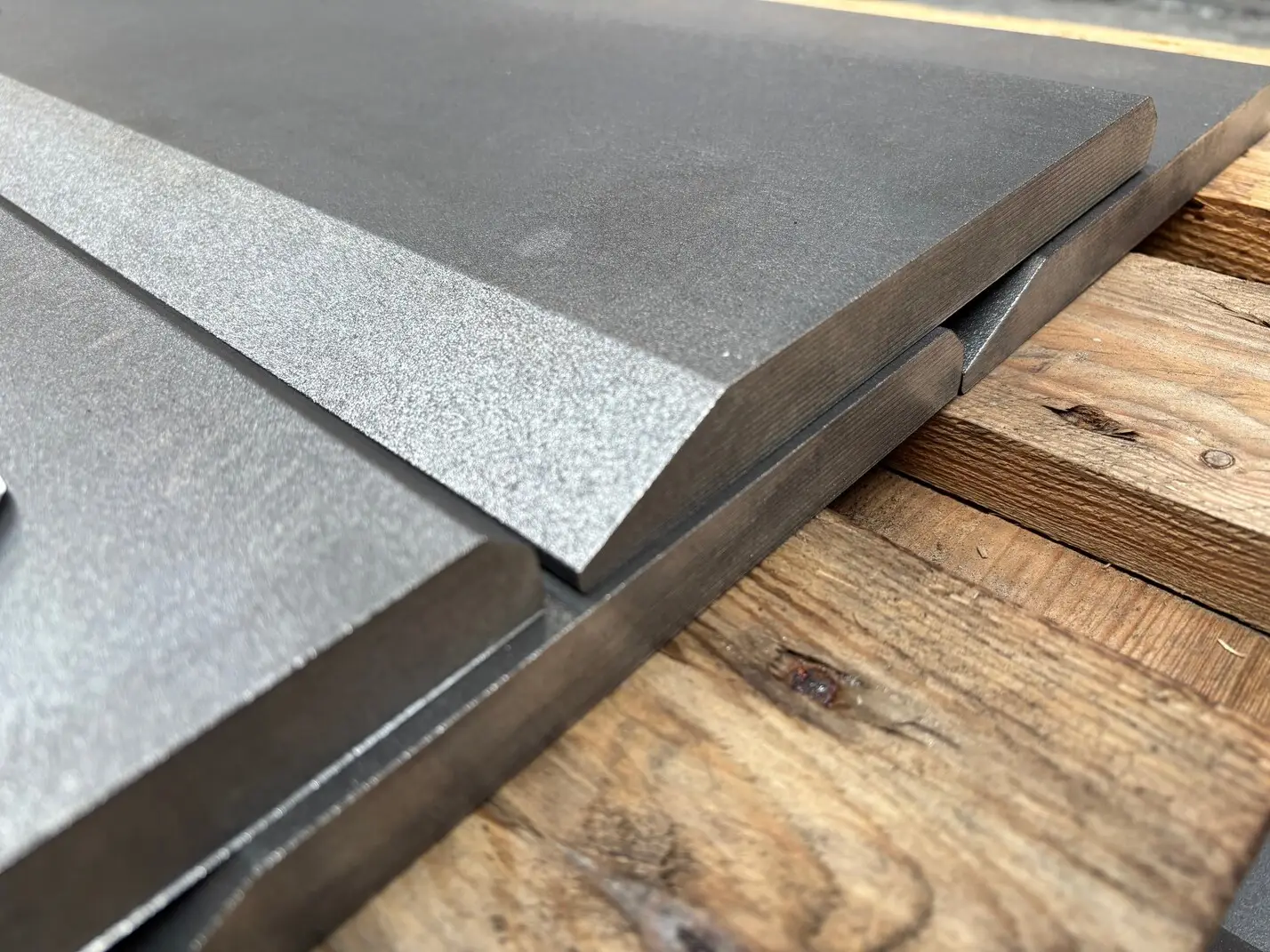

Cutting

We have access to the most advanced cutting technologies to process all types of steel, ensuring high productivity and precision.

Our production lines operate continuously across multiple shifts.

We have been collaborating for years with cutting tool suppliers to develop specific products suitable for processing our steel. Our tool warehouse is constantly replenished to ensure continuous operation of all machinery.

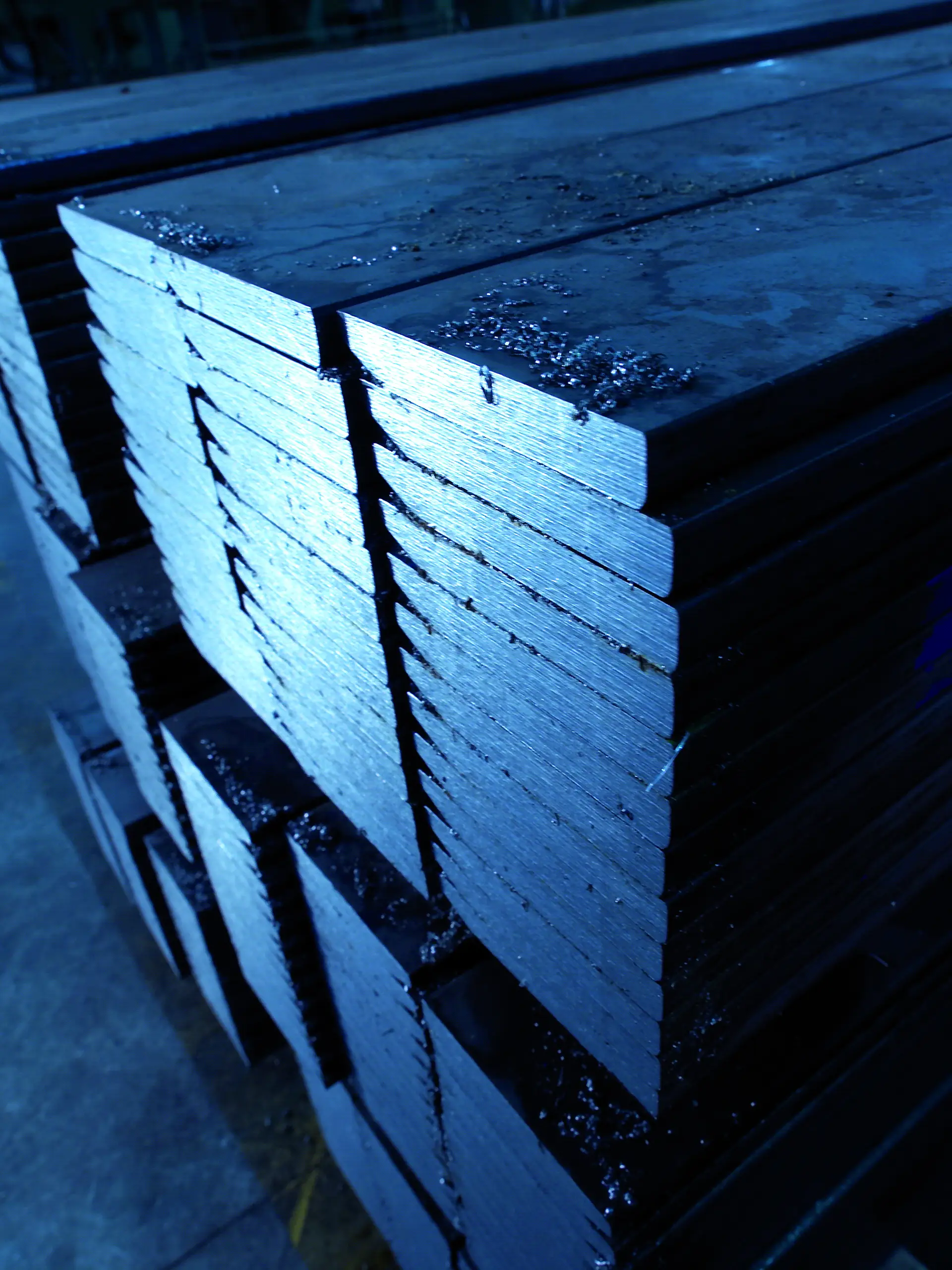

Traditional cutting

We have state-of-the-art band saws, equipped with the best cutting and lubrication technologies. All our lines can process any type of steel, guaranteeing good productivity, both for cutting complete bundles and individual bars.

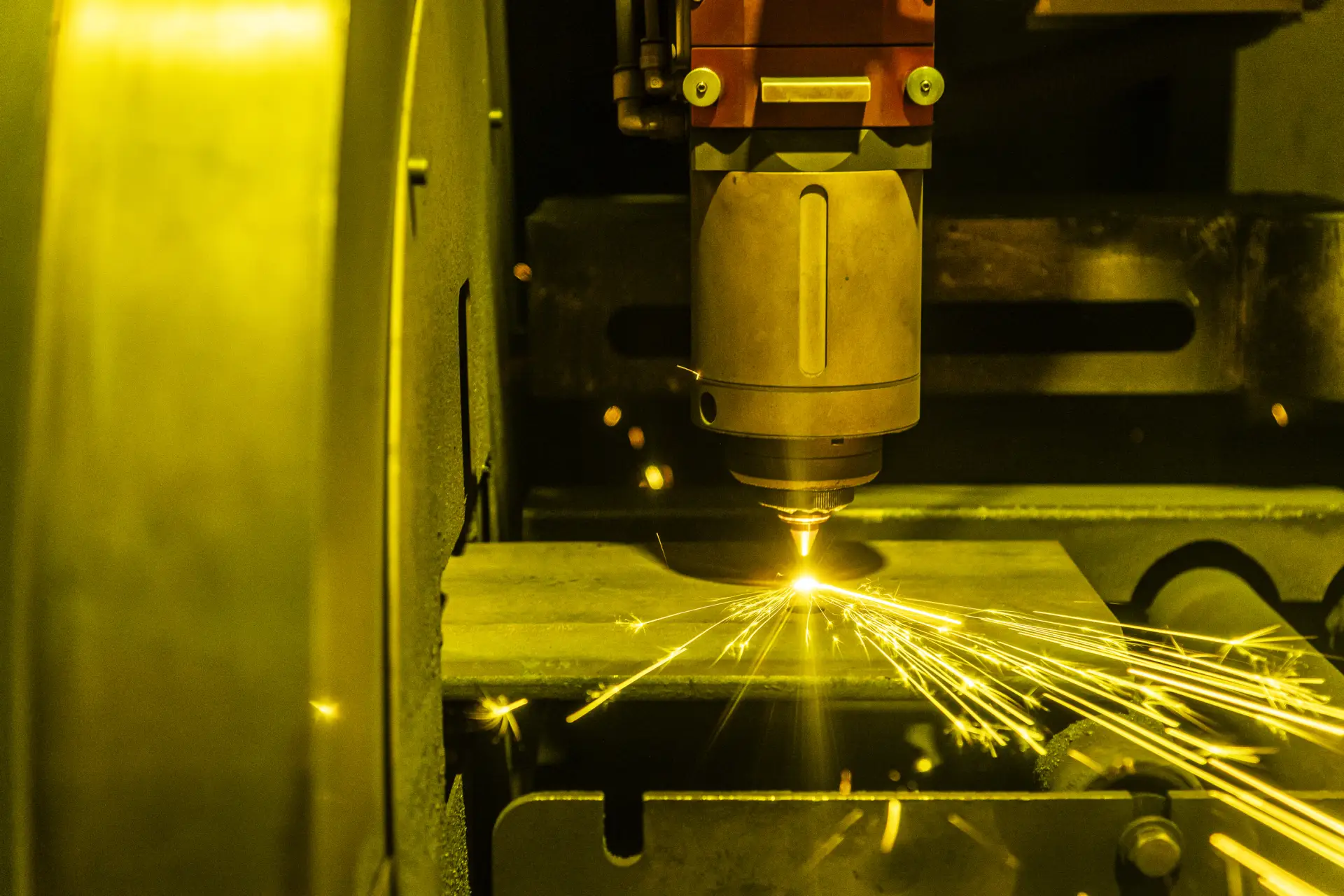

Laser cutting

Our automatic laser cutting line is our most advanced system. It is an integrated line with its own warehouse, two unloading lines, packaging, and labeling.

The system is managed by qualified and skilled operators, who can independently program all operations.

The integration of all phases allows for streamlined production and reduces downtime between phases, significantly increasing productivity.

With this line, we can process large volumes of pieces cut into any possible shape, with the additional capability of drilling any diameter with remarkable precision.

This system was developed in collaboration with industry-leading companies, customizing it to our production needs. The precision in machining ensures compliance with the strictest tolerances, both for cutting and drilling.

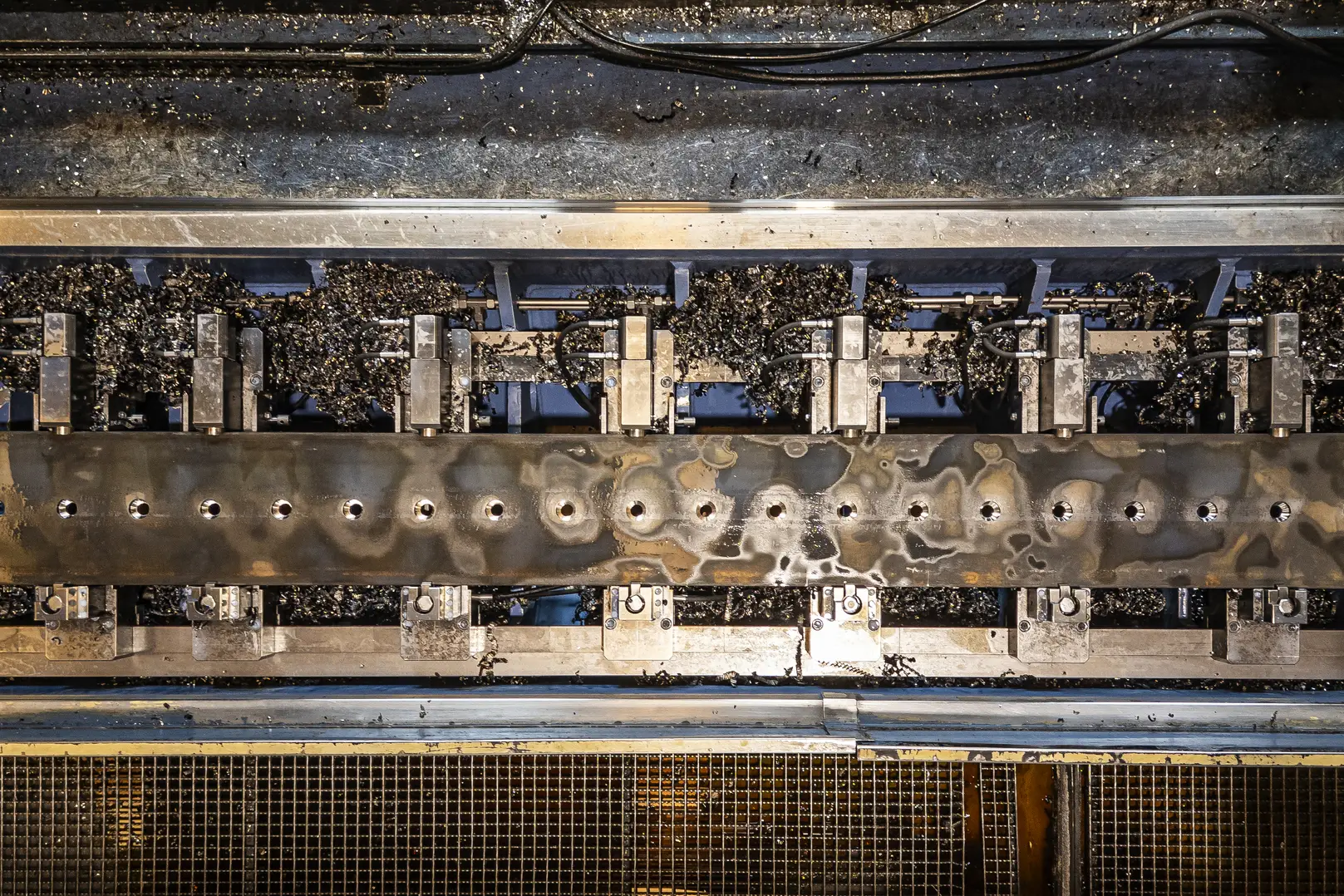

Drilling

Our company has a substantial number of drilling centers, suitable for processing blades of all sizes and steel types, from small pieces to full-length commercial blades that can be drilled along their entire useful length.

In all our machines, we can produce countersunk holes using tools tailored to the typical drilling requirements of the earthmoving sector. We have been working with leading companies in the sector for years to develop tools that are increasingly high-performing and reliable.

Each operation is carefully designed in the technical office and verified by the operators. All of our machines guarantee full compliance with product tolerances.

For each drilled piece, we provide the corresponding bolts and nuts, offering the customer a complete package of products for assembly.

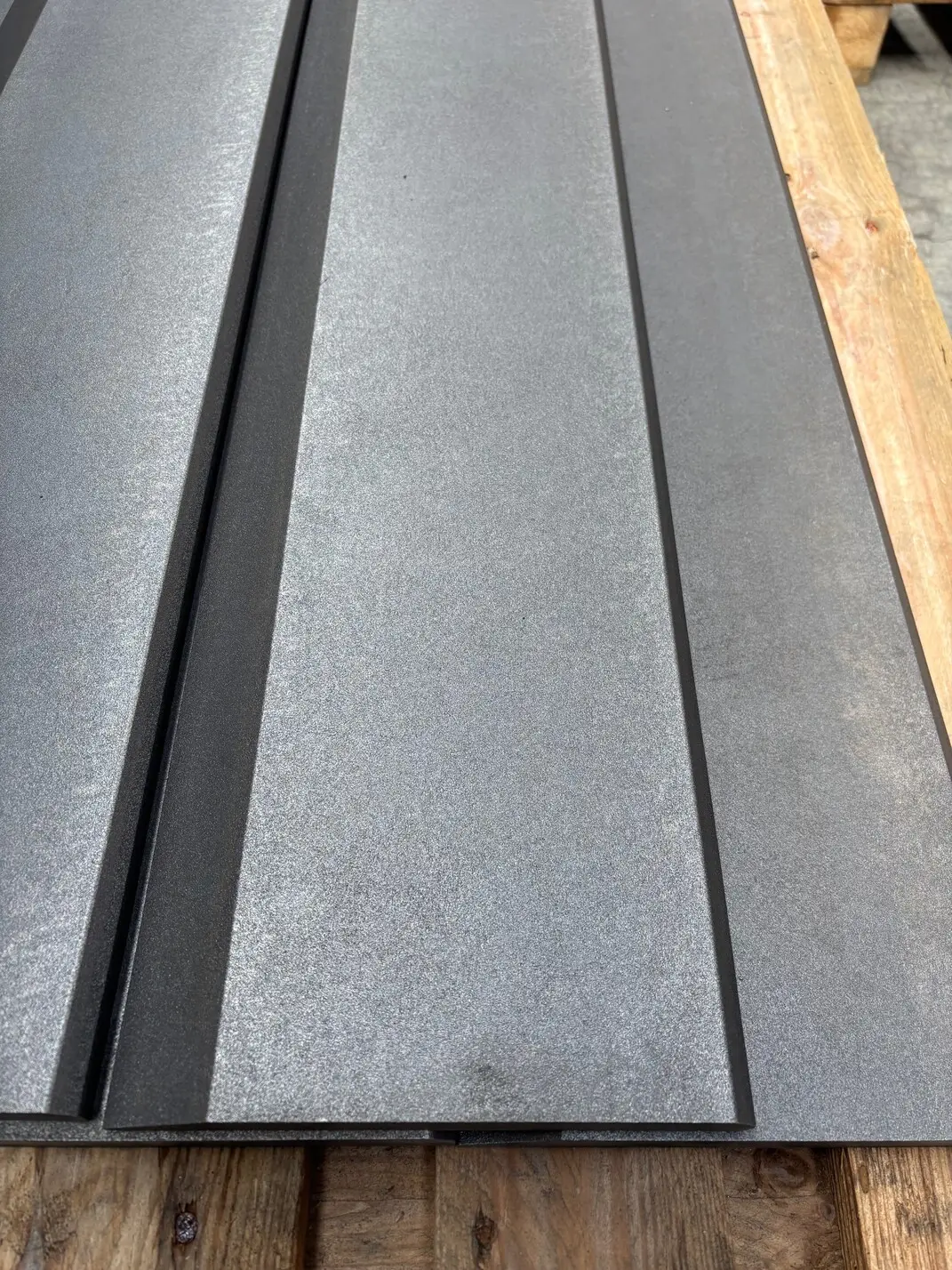

Sandblasting

We have a sandblasting line capable of cleaning the surface of all our products, preparing them for any painting operations. Sandblasted products can be packaged in a way that prevents corrosion during transport.

Painting

Our automatic painting line can handle all items we produce, and we can use any color requested by customers.

The automatic system ensures complete drying and adhesion.

We make it a priority to always use only water-based paints that comply with the latest safety regulations.

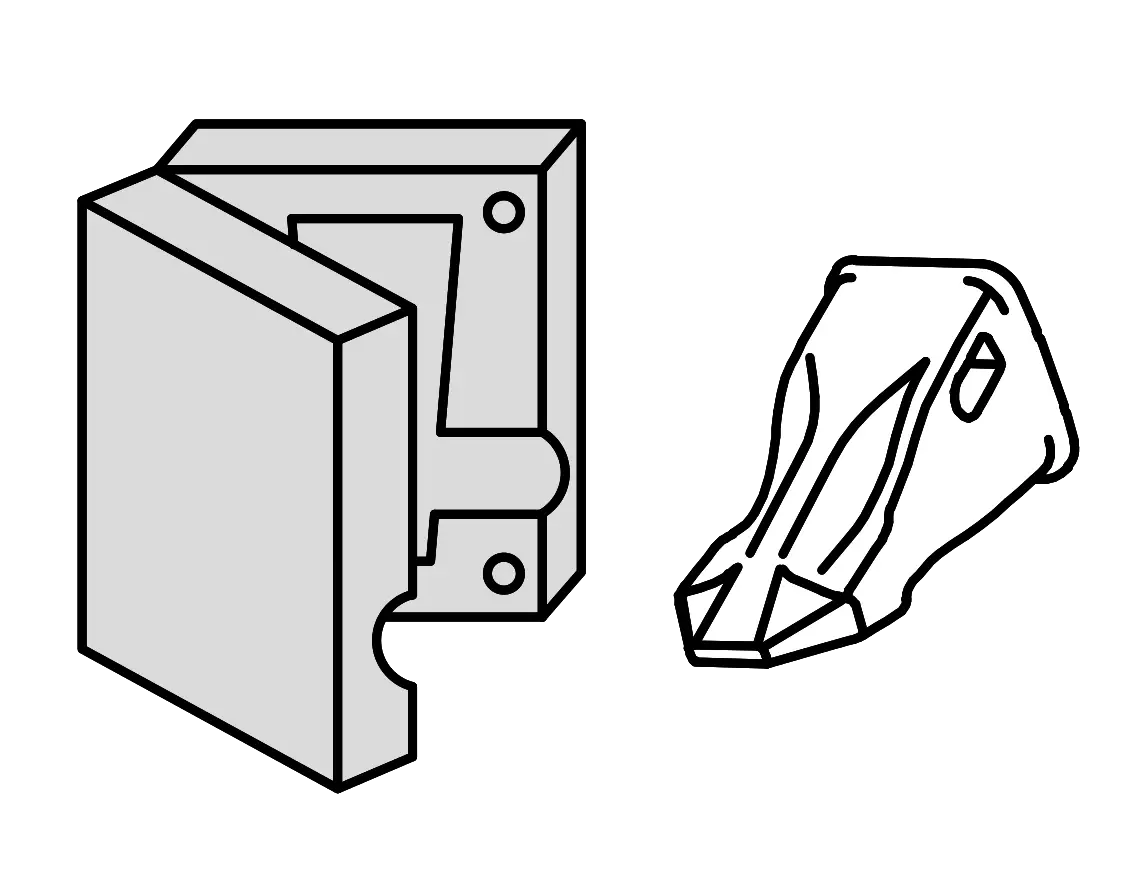

Tooth casting

Our company directly produces all of our teeth in China, using the best types of steel available and the most advanced technologies to achieve finished products of excellent quality.

The casting process is constantly monitored, ensuring uniform analysis for all parts produced and, consequently, uniform mechanical properties.

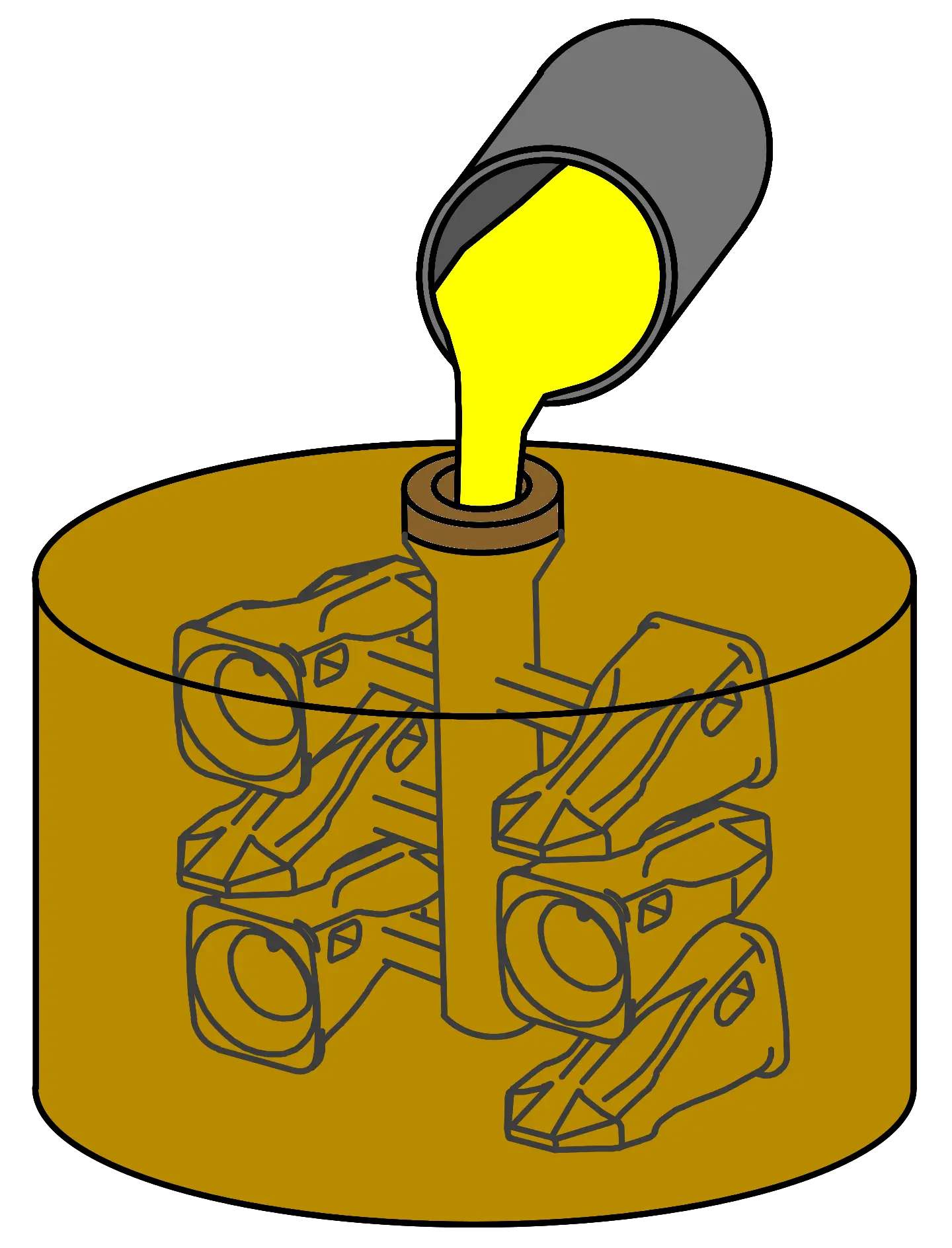

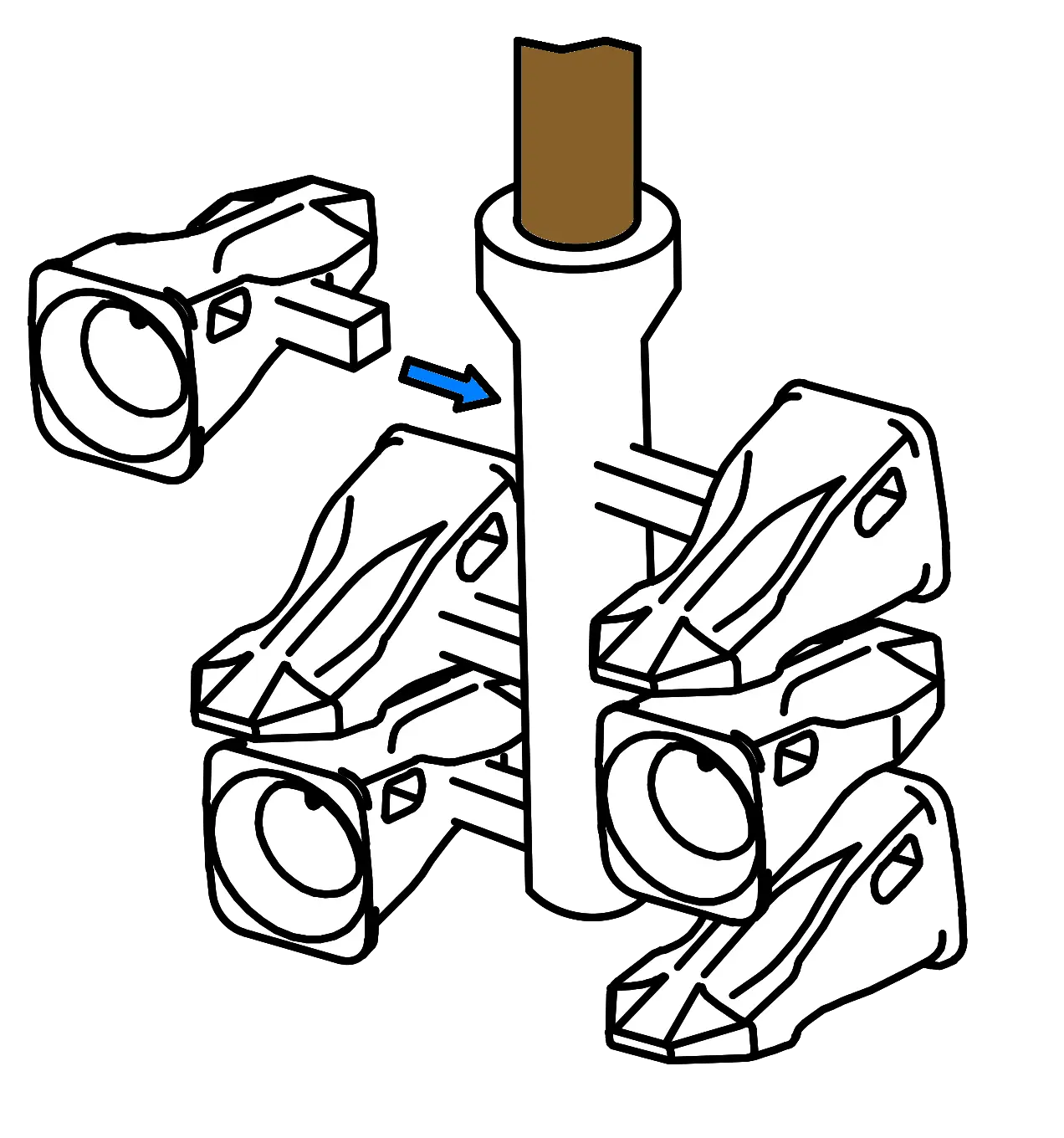

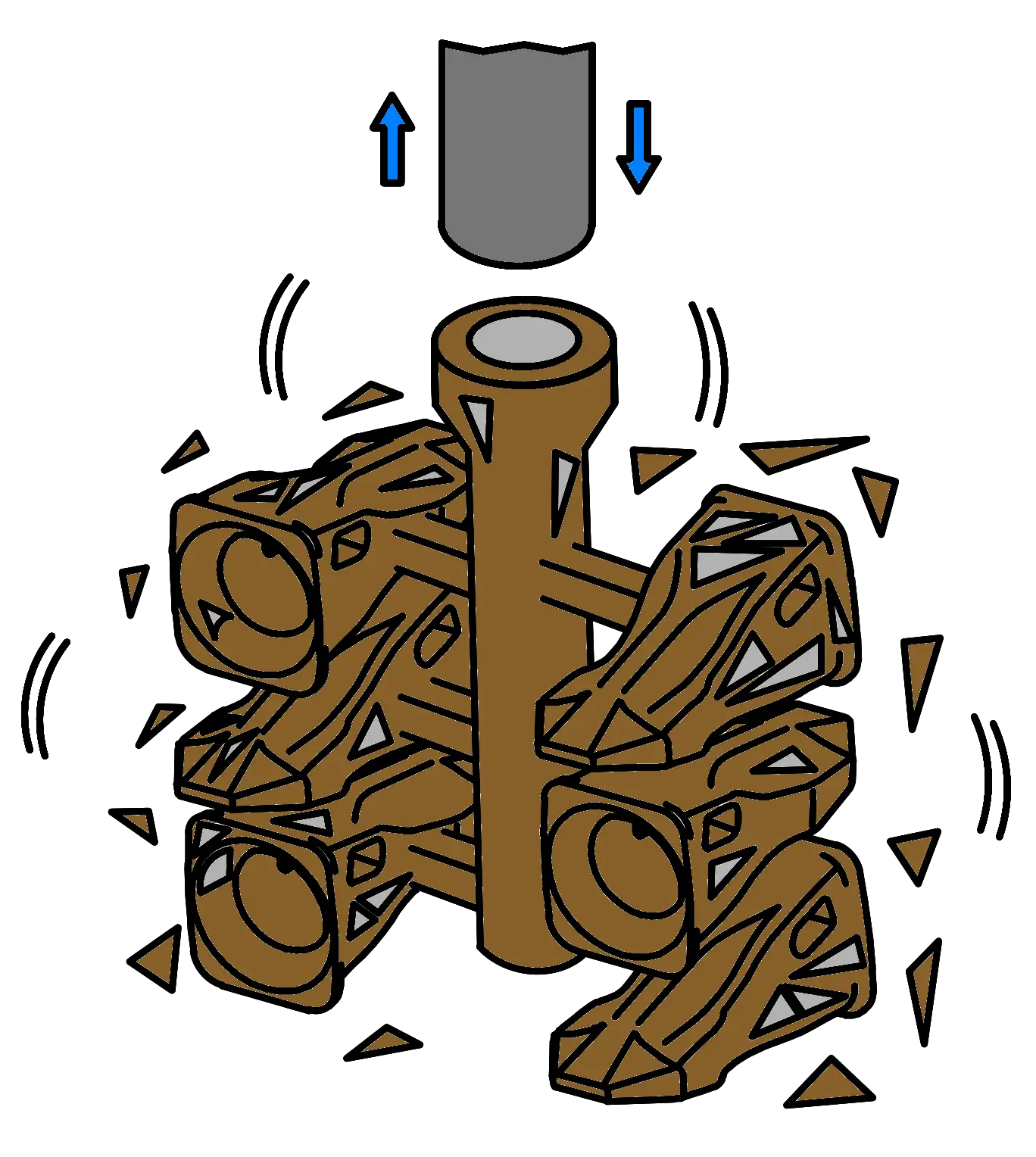

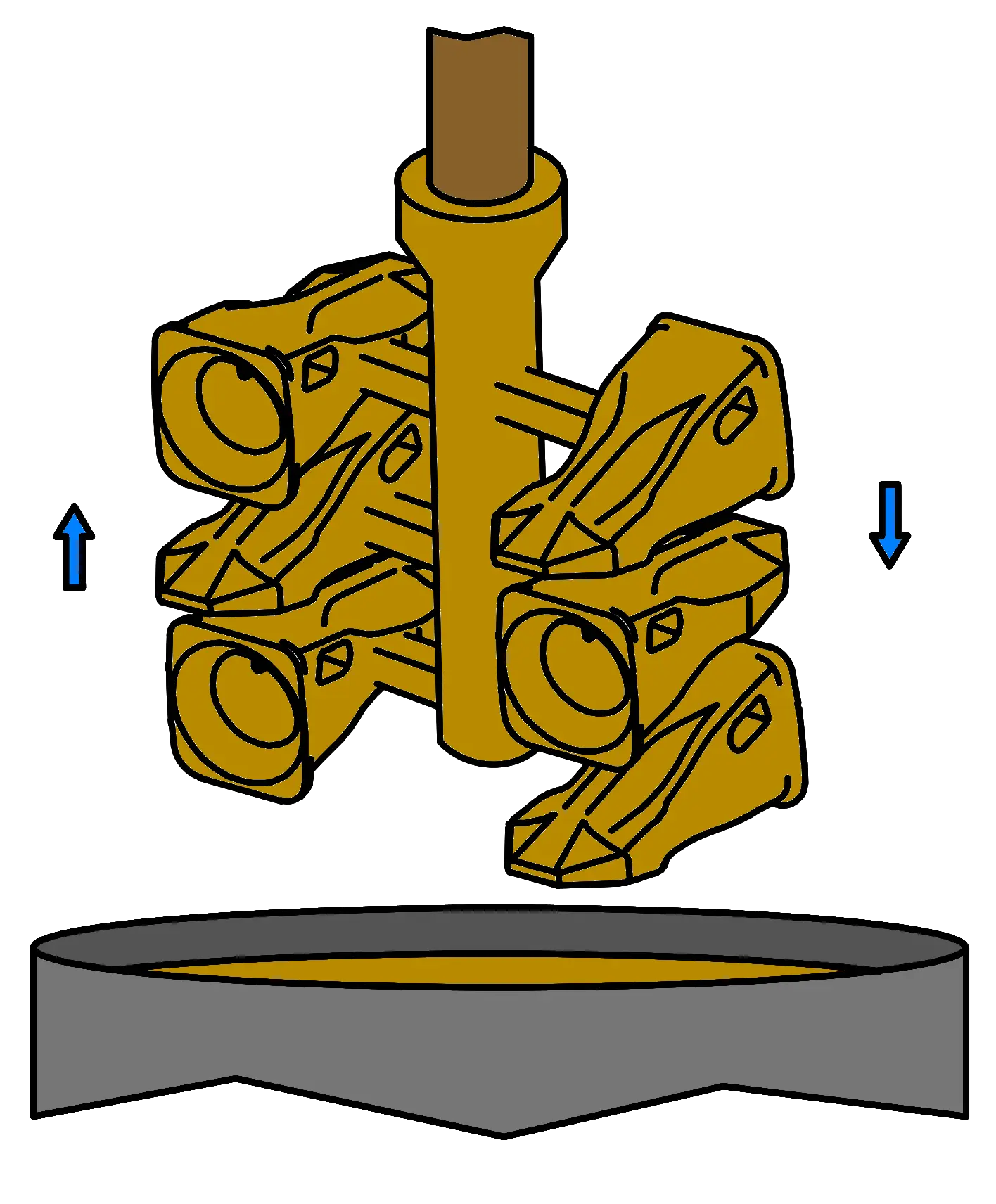

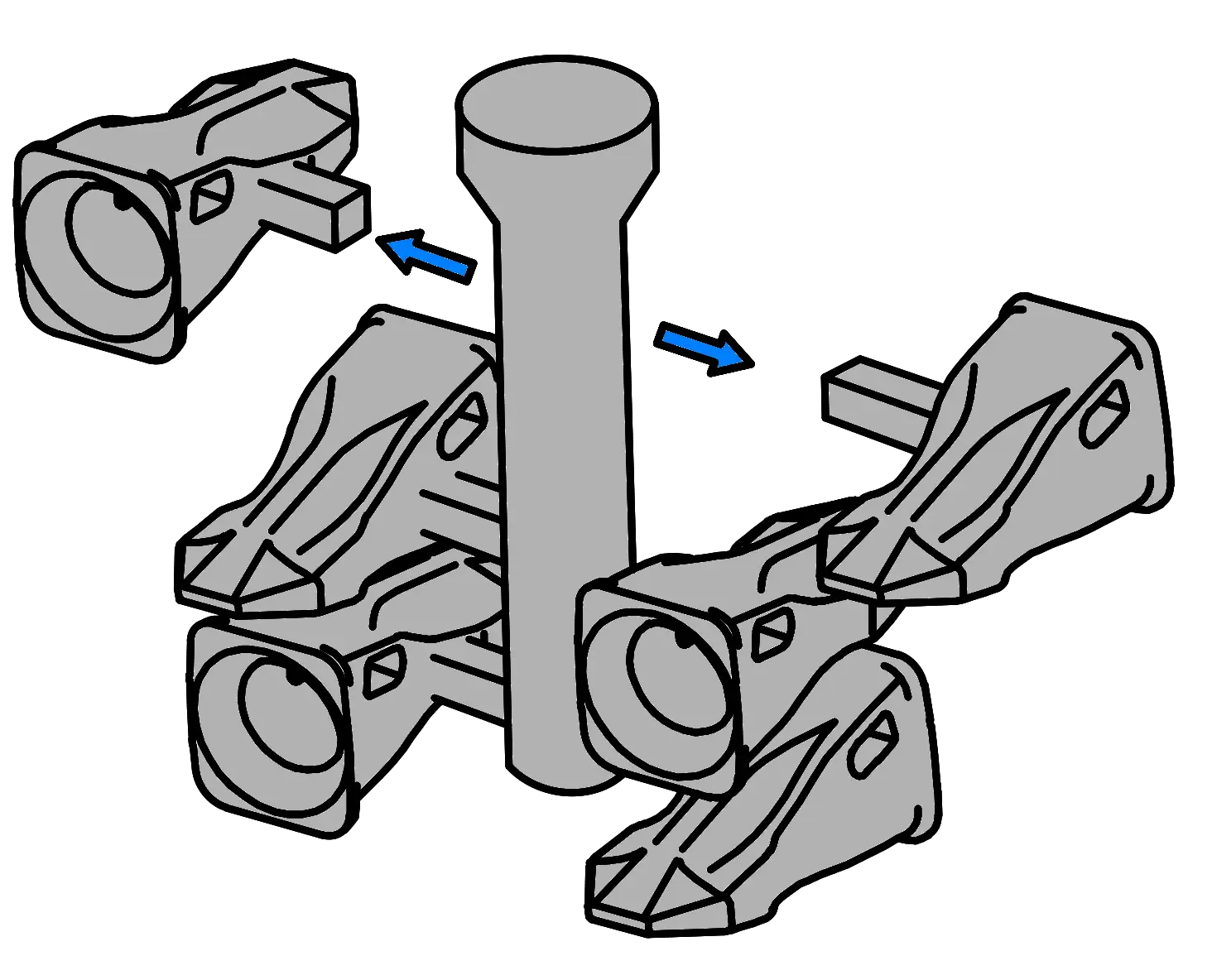

The most commonly used technology is lost foam casting.

This technology allows for the creation of objects in any possible shape with excellent surface quality.

Each of our items has its own mold, with which a polystyrene shape is made. This method is much simpler than traditional lost-wax casting technology because polystyrene has two clear advantages: it is not affected by ambient temperature, and it is very lightweight.

This increases productivity without the risk of shape deformation due to temperature fluctuations, ensuring consistent shape compliance for all finished parts.

Production Cycle via Lost Foam Technology

After the casting process, all our products undergo a complete heat treatment, including hardening and tempering.

The treatment is tailored to the material and specific product, in order to achieve the best mechanical properties for each specific earthmoving application.

Logistics

As the beating heart of the Acciaierie Venete Group, we are committed to the processing and distribution of steel products with precision and reliability. We offer tailor-made solutions for every sales need, ensuring first-class logistics and transportation. Our promise is to deliver the excellence of Italian steel everywhere, with fast delivery times and maximum security, in order to build a stronger future together.

Warehouse

The spacious warehouse is restocked daily thanks to the high internal production capacity, ensuring consistently fast and timely deliveries for the customer.

The Chinese branch of ESTI’s quality office also allows for constant monitoring of production, guaranteeing the high quality that has always set it apart from the competition.

Thanks to the new logistics office, customers can now choose whether to receive materials from the Italian headquarters or directly from the Chinese production unit. This new service results in significant cost savings and a drastic reduction in delivery times for the customer.