A great

Italian excellence

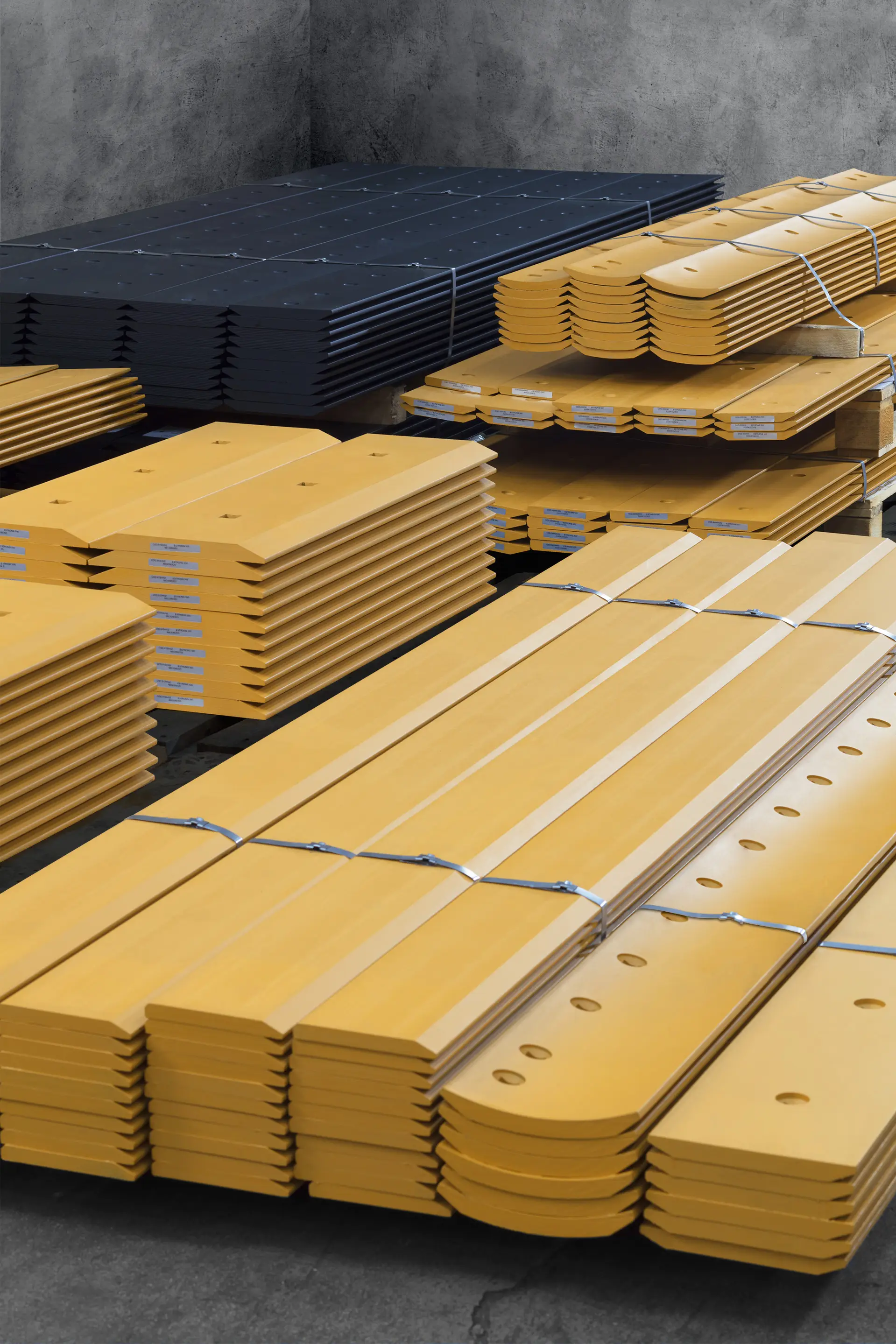

ESTI plays a leading role in the production of wear-resistant steel components.

The company stands out for its intensive research work, which translates into the development of new solutions, the careful selection of materials, and manufacturing processes that have helped make the ESTI brand a symbol of reliability and quality.

Mission

ESTI is an ethical company, made up of people who work every day, every hour, every moment to grow together. Their outstanding professionalism has made the existence of a great Italian excellence possible.

Excellence and Innovation

Production

The know-how accumulated over many years in the industry, the partnership with a Chinese foundry, and the entry of Acciaierie Venete into the company’s share capital have enabled the creation of a lean and comprehensive production system, capable of meeting every need and exceeding the strictest quality tests.

Quality

The careful selection of raw materials, the company’s modern machinery, a laboratory equipped with sophisticated control instruments, and the continuous monitoring of every production phase are just some of the strengths that allow ESTI to guarantee top-quality products to its customers.

Research

ESTI stands out for its intensive research activity, which translates into the development of innovative solutions. Combined with continuous investment, this has made the ESTI brand a symbol of reliability and trust. This research work has also led to the achievement of important patents that have significantly contributed to the company’s growth.

Our history

ESTI is founded with the ambitious goal of becoming a “reference point” in the production of wear-resistant steel components.

1997

2001

With foresight, ESTI begins producing cast parts in collaboration with one of the most important Chinese foundries.

Expansion of the product range, ESTI begins the commercialization of thermally treated, bevelled, laminated profiles under the ESTRONG brand.

2002

2005

Thanks to the skills acquired over the years, ESTI launches the patented “SILVER” series of cast products to the market.

In respect of the beautiful environment surrounding Lake Idro (Brescia, Italy), ESTI expands its production facility to a total of 17,000m², with 9,000m² covered.

2011

2015

ESTI signs an agreement with Acciaierie Venete, a leading European producer of high-quality steel, which acquires a minority stake in the company. This agreement enables the creation of a complete production chain, unique in its kind worldwide, from scrap to the delivery of the finished product.

Growth continues: a new warehouse dedicated to the commercialization of “long blades” is inaugurated, with a new structure covering an area of 8,000m² (of which 5,000m² covered), ensuring greater material availability and faster deliveries.

2018

2020

During a very challenging year due to the global pandemic, Acciaierie Venete acquires 100% of ESTI’s shares.

The ambitious project becomes a reality: with the installation of a fully automated laser system, ESTI doubles its production capacity.

2022

2023

ESTI, highly committed to sustainability, installs a 330 kWp photovoltaic system, making it energy self-sufficient.

During the industry's most important trade fair, Bauma in Munich, ESTI presents its new patented “GOLD” series of cast products.

2025

Our Brands

ESTRONG

High-quality rolled profiles

ESTRONG® is a low-carbon alloy steel with high levels of Boron, Molybdenum, and Nickel, designed to optimize mechanical properties while maintaining excellent weldability and ease of machining.

The high core hardness of the profiles is the result of an excellent chemical composition combined with deep hardening.

Silver Series

The patented SILVER system has established itself on the market for its ease of assembly, shapes designed for excellent penetration, and outstanding strength.

Gold Series

The newly developed and patented GOLD system stands out for its exceptional reliability and assembly safety, with shapes optimized for all ESTRONG profiles produced by our company.

From scrap to finished product:

our identity as a complete steel production chain.

From the management of key raw materials, through the production of long products in special steels, to ESTI’s finished products: a controlled supply chain driven by quality, sustainability, and the excellence of Made in Italy.

Through the daily commitment of our employees and collaborators, we ensure maximum reliability for those who use our products and semi-finished goods. A unique value chain, united by shared values, that begins with in-house scrap collection and selection, and the procurement of renewable energy, continues with the supply of a wide range of long products in engineering steel, and culminates, with ESTI, in the production of patented wear-resistant steel components for the earthmoving industry.

Processing and sale

of scrap

Collection and internal management of scrap for steel production: a virtuous example of circular economy.

Processing and sale

of scrap

Collection and internal management of scrap for steel production: a virtuous example of circular economy.

Sustainable energy

Supply of sustainable energy for Acciaierie Venete, aiming at 100% of energy from renewables by 2030.

Production of engineering steel longs

With eight production plants in northern Italy, Acciaierie Venete is one of the biggest European makers of special steels in the longs market.

Cold processing and sale

of steel products

CIA is the ideal connecting link between steel, made entirely by Acciaierie Venete, and the applications world.

Production and sale of wear-resistant steel

for earthmoving machinery

Among the world's leaders in the production of replacement parts in patented wear-resistant steel for the agricultural and earthmoving sectors.

Other group companies

The world of Valle Zignago

To assist with conservation of a territory that is an integral part of the Group's cultural and geographical roots beyond our steel industry role, in 2020 Acciaierie Venete acquired the Valle Zignago agricultural estate, allowing us to return part of the economic value generated to our local area.

Valle Zignago is at the northern end of the Caorle valley system (Venezia), consisting of 400 hectares of wetlands, narrow sandbars (typical of the lagoon landscape), embankments and farm roads, 410 hectares of cultivated farmland and 4.5 hectares of land annexed to residential and agricultural buildings, administrated by the Olmo Immobiliare real estate agency.

The area is a nature reserve and a paragon of biodiversity, a green jewel that we manage and preserve as a symbol of the Group's commitment to nature and the surrounding community.

Real Estate Company

Nature Reserve

in the Caorle and Bibione Lagoon Area

Financial Company